Objectives of the project:

Development of a catalyst for the vapor phase selective direct oxidation of benzene to phenol in onestep is the main objective of the project.

Highlights of the work :

1. IICT developed a Cu-V-Sb nano particles dispersed CuCr2O4 spinel catalysts for the selective preparation of phenol by direct hydroxylation of benzene to phenol.

2. Demonstrated the performance of IICT heterogeneous catalyst for gas phase continuous flow reaction withan optimum Benzene conversion of 18% with 61% selectivity to phenol.

3. Established a reactor system with complete mass balance and carbon balance with all product details.

4. Establishedanalytical methods for analysis of products, catalyst synthesis, characterization and experimental data with process optimization.

5. Submitted the SOP for catalyst synthesis and catalyst evaluation for benzene hydroxylation.

6. Catalyst stability is demonstrated for continuous operation of 24 h.

CSIR-IICT has developed a non-catalytic continuous thermal bromination of monobromomethane to Dibromomethane (DBM). The raw materials for Dibromomethane are methyl bromide and bromine. The process is highly efficient with selective bromination towards DBM. DBM is currently imported as there are no manufacturing firms in India. It is the starting material for synthesis of the several organic compounds and is widely used in pesticide field for synthesizing CH2(SCN)2, C9H22O4P2S4 etc. The process developed at CSIR-IICT is indigenous and can benefit the Indian Industries dealing in bromine based technologies. The process was demonstrated successfully to the for M/s Intech Organics, Gurugram, Harayana.

A five step-process for the preparation of an imidazole class of fungicide, Cyazofamid, is developed at CSIR-IICT on 100g scale starting from toluene. All the raw materials used are indigenously available.

The whole process was successfully demonstrated to Insecticides India Ltd (IIL), New Delhi.

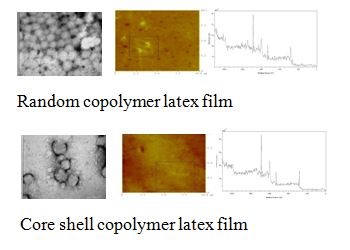

Fluoroacrylate (FA) copolymers have low surface energy and related hydrophobicity, very good chemical resistance, thermal stability and low flammability which make them a prominent choice for application as protective coatings. Generally, copolymers of fluorine free acrylates are used along with FA in coatings such that during film formation, FA preferentially stratifies to the film-air surface while the fluorine-free acrylates migrate towards the inner layer and provide good adhesion with the substrate. It is known from literature that the surface properties of FA copolymers are related to the organization of fluorinated side chain and is governed by the fluorinated chain length, the chemical structure, and the flexibility of main chain. The properties of FA copolymers can be improved by increasing the amount of the fluorinated monomer, but is impractical due to the relatively high market prices of the fluorinated acrylate monomers. Therefore, design of core shell architecture composed of fluorine-free acrylate core and fluorine-containing acrylate shell can effectively enhance the properties because of the convenience in stratification of the fluorine rich shell components on the surface of the film in comparison to the random copolymer latex. Thus, core shell morphology of the latex particles results in improved hydrophobic property using minimum FA at a reduced cost. In the present paper, our experience on synthesis of core shell latex particles with MMA cores and BA-FA shells and a comparative study on the influence of core shell nanoparticles morphology and percentage of fluorine atom concentration in FA monomer with the random copolymers on the surface properties of copolymer emulsion shall be presented. The results eventually helped select latex that has optimum hydrophobic properties for application in protective coatings.

Sodium salt of 3,5,6-trichloro-2-pyridinol (Na-TCP) is an important high volume import chemical and n-1 intermediate in the manufacture of Chlorpyriphos. PMFAI sponsored this project with an objective to re-investigate the existing process, improve the yields so as to be economically competitive. Accordingly, studies have been conducted, emerged with an alternate route to accomplish the goal. Thus, developed process know-how was successfully demonstrated to PMFAI on time frame.

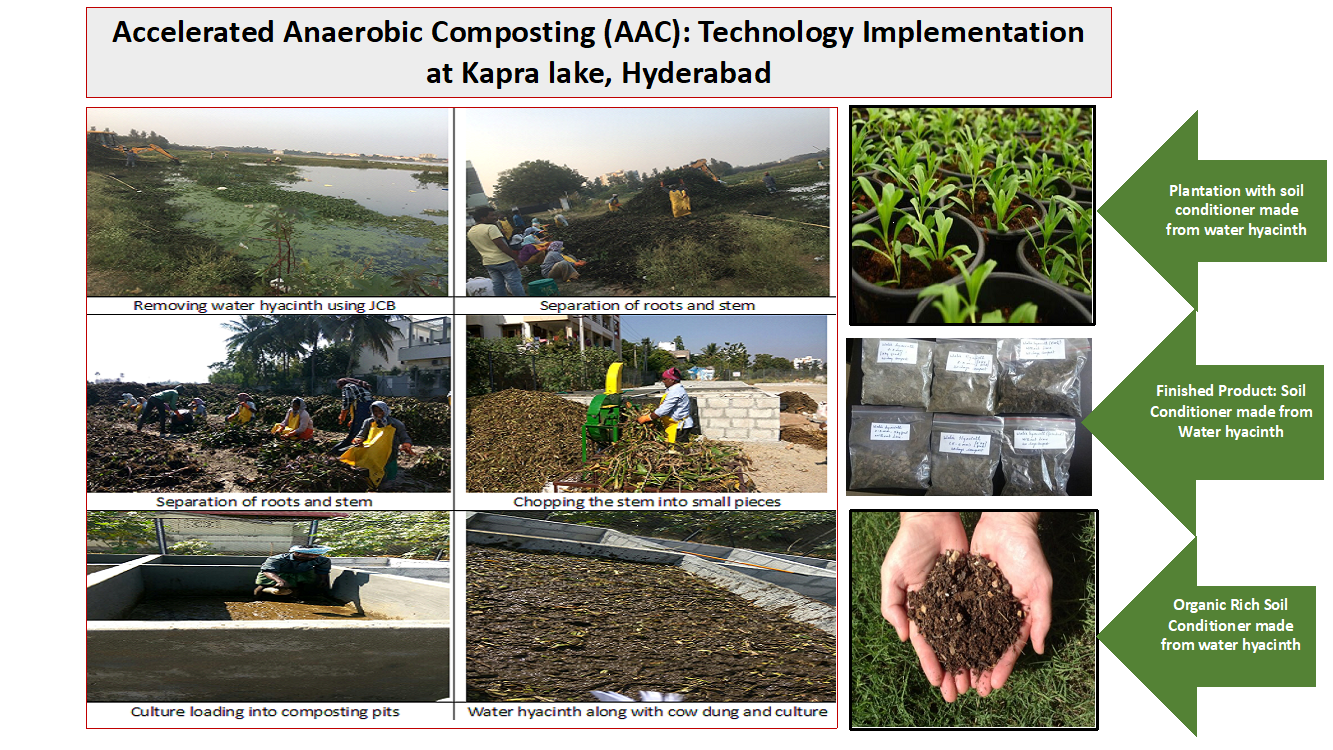

Wealth out of waste - Health out of waste: Organic rich enriched nutrient soil conditioner Water Hyacinth

Water Hyacinth (WH) grows in areas abnormally depleting the Dissolved Oxygen levels of water bodies effecting the aquatic life cycle of the water bodies but cleans the pollution generated by sewage entering it, and also reduces the CO2 emissions around the water body. BEES lab of CSIR-IICT has developed a technology to make water hyacinth (WH) into a soil conditioner through Accelerated Anaerobic Composting (AAC). KHAR Energy Optimisers (KHAR) in association with IICT commercialized the AAC Technology to Convert WH to a good quality Soil Conditioner for rejuvenating soils for better fertility. The completion of a total cycle of the conversion of WH to an enriched farm output is now considered to make this process scaled up for commercial production with more automation for cost cutting and better yielding.

CSIR-IICT has developed Modular High Rate Biodigester at compact level and transferred to M/s. Lars Enviro Pvt. Ltd., Hyderabad. It will be extensively used for organic solid waste management based on High rate biomethanation technology.

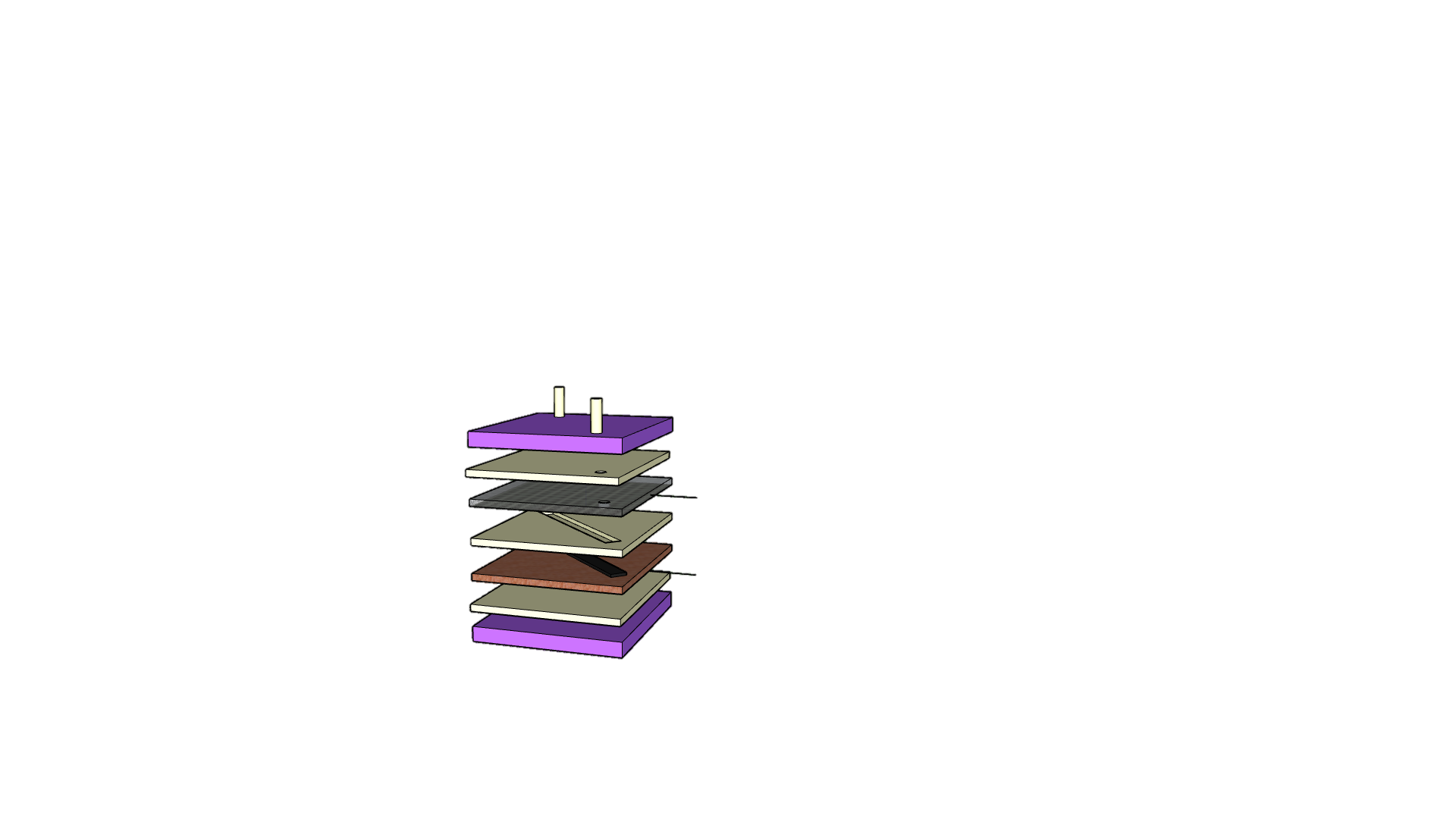

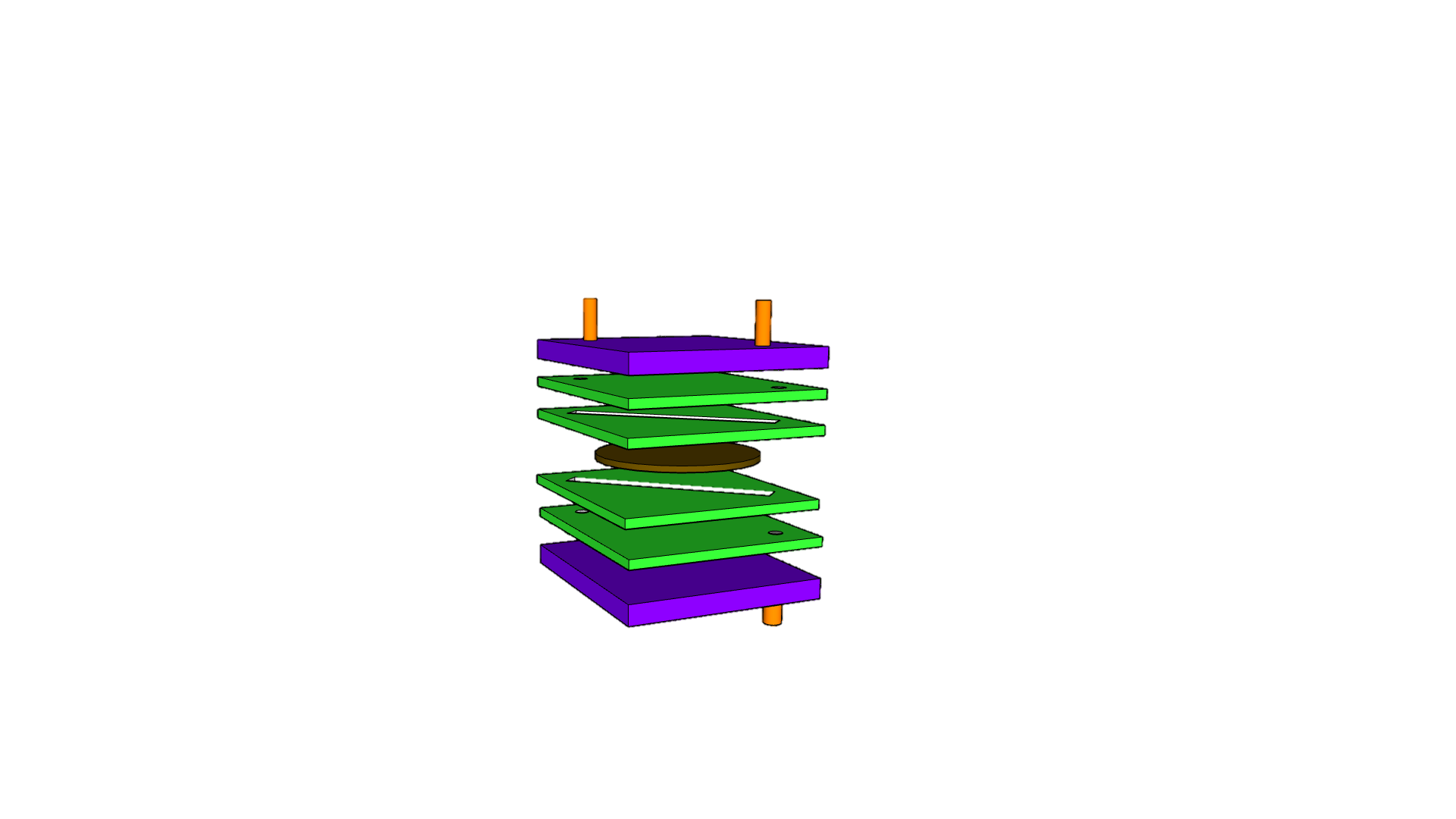

For the organic chemical transformation series of the oxidant or reductant need to added but it’s generate huge environmental problem. Electricity is cheaper and economic substitute for the oxidant and reductant. Here, we have developed first Indian made, electro-flow reactor containing patterned electro-deposited nanoparticles as working electrode for various organic reaction in a co-reductant/oxidant-free manner.

Syrris(UK) made electro-reactor price = 18 lakh

Our reactor with same feature = 0.4 lakh

New employee generated = 100 and in future may be 10000 person.

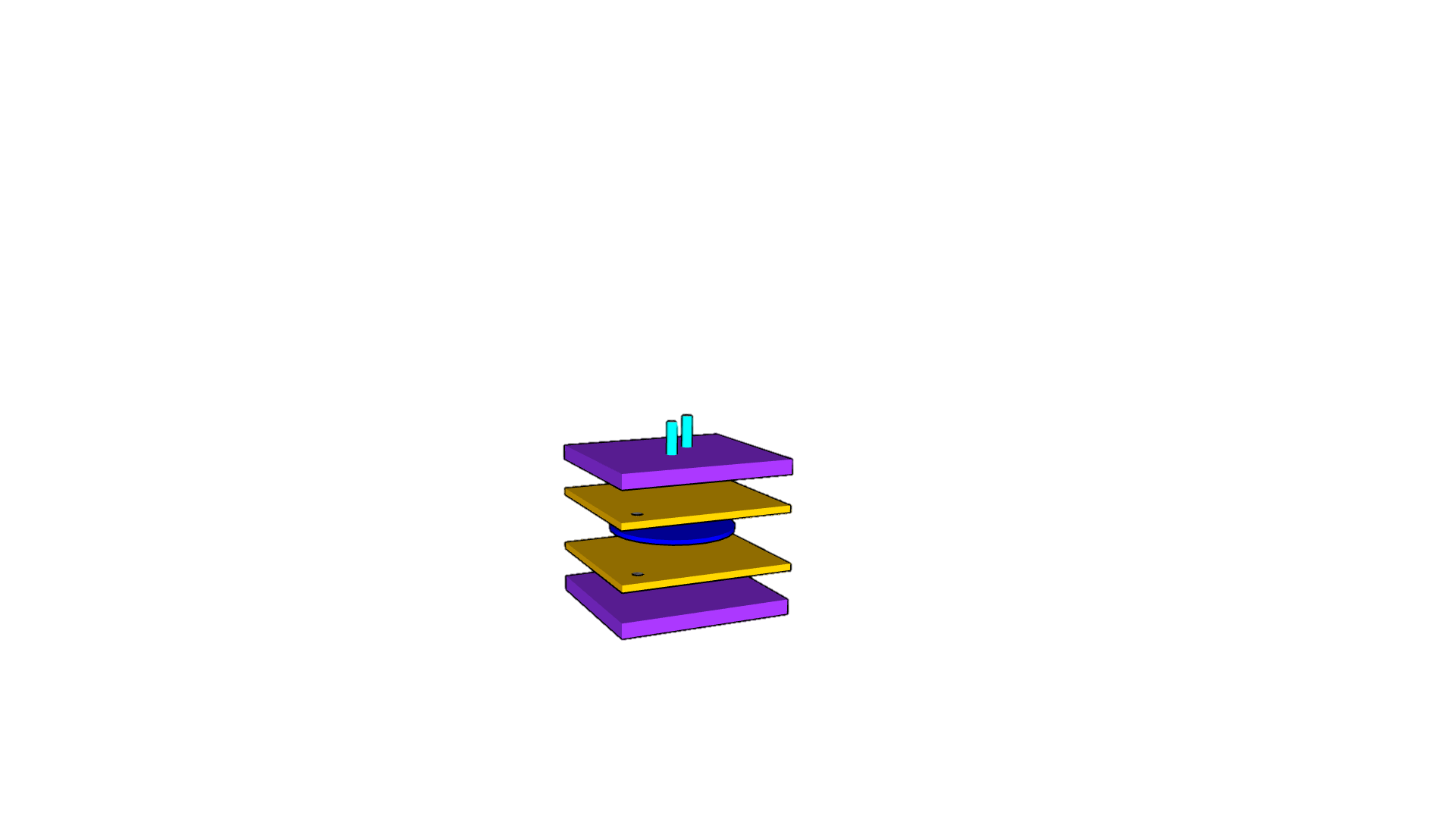

In general, after the organic reaction number of post-synthetic tedious work-up process needed to separate the organic product from the reaction mixture. To reduce the hug man-power involvements for waste chemicals removal, we have developed first Indian made continuous flow liquid–liquid extractor, for selective removal of waste chemical from the product mixture.

Zaiput(USA) made separator price = 3 lakh

Our reactor with same feature = 0.2 lakh

New employee generated = 500

In future may be 50000 person will engaged.

In continuous flow chemical manufacturing, to control the pressure in the reactor side we have develop manual back pressure regulator to control the pressure.

An inexpensive Import Substitute was developed by Dr. S. Sridhar and team members of Membrane Separations Group, PETT Division of CSIR-IICT, Hyderabad for production of ultrapure water for dialysis and other applications in different fields. The ultrapure water technology consists of compact low cost cascaded RO membrane modules with booster pump, pre-filter and post-filter cartridges pressure gauges for producing Type-3 water of resistivity 2–3 mega Ώ cm as per ASTM standards. For generating Type-2 water a specific mixed bed ion exchange resin column is included. The cascaded compact membrane system of 25–50 Lit/hr capacity costs Rs. 0.8–1.0 lakhs only, whereas the pilot plant of 500 Lit/hr costs Rs. 3.0–4.0 lakhs only (Selling prices inclusive of 50-60% profit margin). Post treatment treatment also includes UV lamp to eliminate miccrobial contamination from tubing or contact parts. 03 Pilot plants of 500 L/h installed in Nephroplus chain of hospitals at Nandyal, Kamareddy & Marredpally has served > 20,000 dialysis patients suffer from chronic kidney disease

CSIR-IICT has developed an indigenous pilot plant for production of drinking water via

the modified membranes. The process involves pre-filtration after which the water is

passed through the modified NF functional membrane modules which allow passage of

sufficient minerals for consumption (> 80ppm) and for removal of soluble inorganic salts and natural organic matter. Auroma Clean Energy Pvt. Ltd. have been selling 20 L water cans to local residents and shops.

This invention relates to identification of Oroxylum indicum, Indian medicinal plant as a rich source for flavanoids. We have identified mucoprotective and antigastric ulcer properties in the flavone class of compounds. The invention also provides a flavanoids mixture obtained in Substantial yield from hexane and acetone extracts. The hexane extract was fractionated, purified and the compounds identified alpha-glucosidase inhibitory properties for Oroxylin A, Chrysin and Baicalein.

The anticancer formulation licensed to NanoDev Therapeutics (NDT) has shown the potential to treat drug resistant, relapsing cancers using even low-cost generic drugs. It exhibits the classical potential to repurpose many existing generic drugs making them relevant for treating multiple phenotypes of cancer. As a result NDT in collaboration with Mayo Clinic, USA (the co-patentee of this product) has further refined the formulation to treat humanoid models of hematological cancers, previously untested by us. NDT is actively scouting for investors to take forward the formulations in phase clinical trials in USA and India.